Carbon film resistors play role in managing electrical resistance (and therefore electric current and voltage) in both simple and complex electronic devices. Whether you’re a beginner or a pro in electronics, knowing how these resistors work can make your projects more reliable and efficient. In this post, we’ll break down what a carbon film resistor is, how it functions, and why it’s important for different applications.

What is a Carbon Film Resistor?

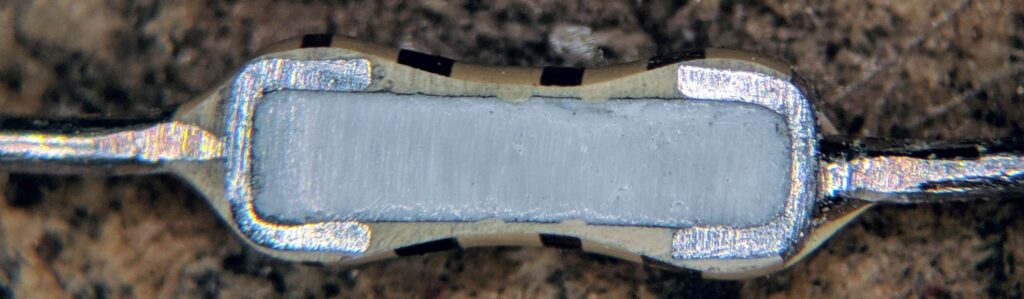

A carbon film resistor is a type of resistor where a thin layer of electrically conductive carbon is deposited onto electrically non conductive ceramic substrate to create resistance. This method forms a fixed resistor with stable properties. The resistance is controlled by adjusting the thickness of the carbon film.

Resistor key components:

- Carbon Film: A thin layer of carbon that conducts electricity but also provides resistance.

- Ceramic Substrate: A non-conductive base that holds the carbon film in place.

- Leads or Terminals: The metal ends that connect the resistor to the circuit.

All the above-mentioned parts can be seen in the image below. The tiny black part between the ceramic substrate and the insulating housing is actually the conductive carbon film of the resistor.

How Carbon Film Resistors Work

Carbon film resistors work by impeding the flow of electrical current. The carbon film acts as a barrier, slowing down the current, and turning some of the electrical energy into heat. The amount of resistance is determined by the thickness of the carbon film—thinner films provide more resistance.

Step-by-Step Process:

- Electrical Current Enters: Current flows into the resistor through the metal leads.

- Resistive Layer: The carbon film resists the flow of electricity, converting some of it to heat.

- Current Exits: The reduced electrical current exits the resistor and continues through the circuit.

This process helps control the voltage and current in a circuit, protecting sensitive components from damage.

Why Carbon Film Resistors Matter

Carbon film resistors are favored for several reasons:

- Cost-Effective: They are inexpensive to produce, making them a popular choice for consumer electronics.

- Temperature Stability: These resistors can handle high temperatures without significant changes in performance..

- Low Noise: Carbon film resistors produce less electrical noise compared to carbon composition resistors, which is beneficial for audio or radio frequency applications.

Whether you’re assembling a DIY project or working on a professional-level design, carbon film resistors ensure the stability and performance of the electronic device.

Common Applications

Carbon film resistors are used in multiple applications because of their balance between cost and efficiency. Here are some common places you’ll find them:

- Consumer Electronics: In radios, TVs, and computers for stable resistance control.

- Power Supplies: Used to manage voltage in regulated power supply circuits.

- Test Equipment: In devices that measure electrical parameters to ensure accuracy.

They are suitable for general-purpose electronics but may not be ideal for highly precise applications.

Key Benefits and Limitations

Benefits:

- High Voltage Resistance: These resistors can handle higher voltages compared to some other types.

- Wide Availability: Easily found and used in countless electronic circuits.

- Durability: They perform well in high-temperature environments.

Limitations:

- Accuracy: Carbon film resistors have a higher tolerance range, meaning their resistance value might not be as precise as other types like metal film resistors.

- Heat Sensitivity: Though stable at high temperatures, excessive heat can cause the resistance value to drift over time. Carbon-type resistors have a poor negative temperature coefficient (typically -0.0005), so they are not well suited for precision applications requiring little resistance change over temperature.

So for example 0.125 Ohm resistor at 20°C will have resistance of 0,121 Ohm at 85°C:

R(T) = R_ref [1 + α (T – T_ref) ]

= 0.125 Ω [1 + -0.0005 (85 °C – 20 °C) ]

= 0.1209375 Ω

= 0.121 Ω

Also another example: if you heat a 1000 Ω resistor by 10 °C then it will have a resistance of 1000 Ω *(1-0.0005*10) = 995 Ω.

How to Choose the Right Carbon Film Resistor

When selecting a carbon film resistor, here are some factors to consider:

- Resistance Value: Measured in ohms (Ω), this determines how much the resistor impedes current. Almost all resistors on market have standardised resistor values.

- Power Rating: Measured in watts (W), this tells you how much power the resistor can handle before it overheats.

- Tolerance: This indicates how close the actual resistance is to the labeled value. Common tolerances for carbon film resistors are ±5%.

- Temperature Coefficient: Shows how the resistance changes with temperature (examples above).

By evaluating these parameters, you can choose the right resistor for your project’s specific needs.

Conclusion

Carbon film resistors are essential components in many electronic devices, offering a balance between performance and cost. Their wide range of applications, from consumer electronics to industrial equipment, proves their versatility and reliability. Understanding how they work and selecting the right one for your needs can greatly enhance your project’s success.

Leave a Reply