While logic devices are often referred to as the glue that holds electronic designs together, they’re sometimes overlooked when selecting components for a system. Although standard logic devices have been widely used for years, the growing complexity of designs demands more integration to allow room for additional functions.

More engineers are turning to programmable logic devices (PLDs), complex PLDs (CPLDs), or field-programmable gate arrays (FPGAs). These devices help minimize solution size, cut down on design and manufacturing costs, streamline supply chains, and speed up the time to market. When working with CPLDs or FPGAs, you have a range of trade-offs to consider. They support thousands of logic elements, come in diverse package sizes, and may require advanced programming expertise.

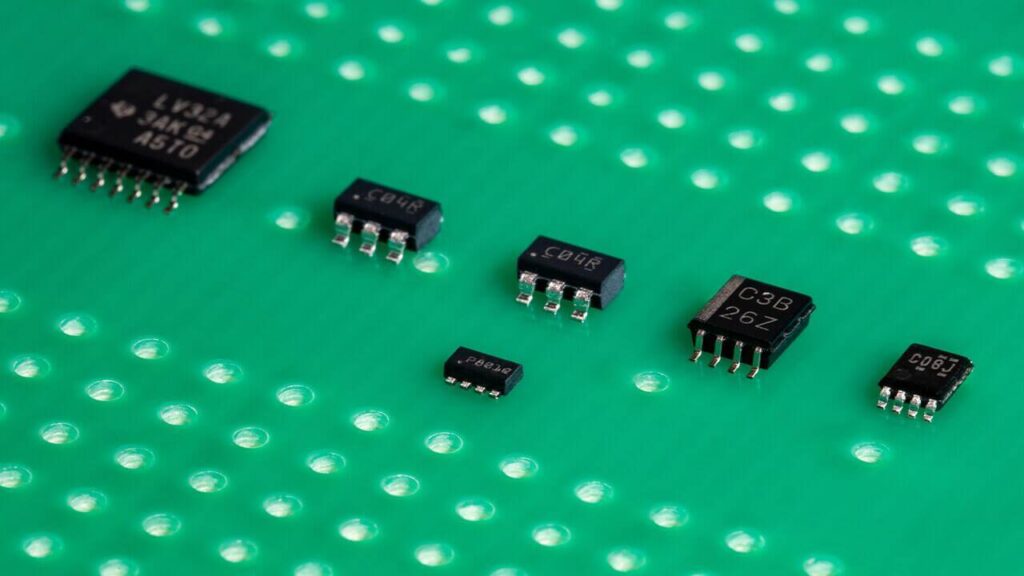

Newer PLDs, such as those from Texas Instruments (TI), integrate a wide range of sequential logic and analog functions into a single package. This reduces board space by 90% or more and slashes the number of components needed by over 80%, compared to traditional discrete logic implementations.

Configurable Logic for Your Needs

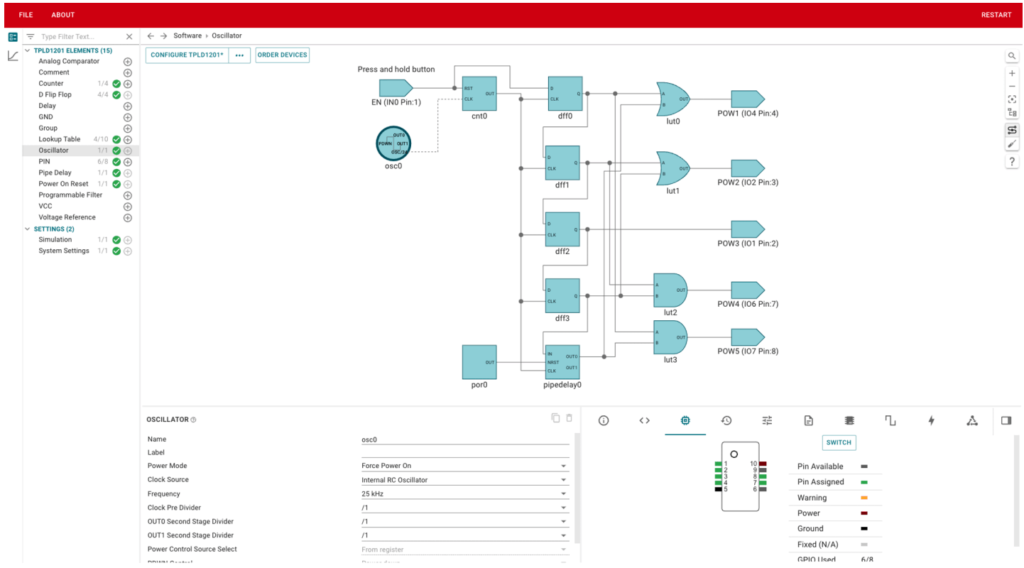

TI’s PLDs offer a mix of logic functions, D-type flip flops, counters, pattern generators, and more. You won’t need to redesign hardware to add new functions or parameters. Instead, you can leverage configurable logic elements to meet your design’s performance needs without requiring coding experience or specialized software development.

Programmable Logic in Standard Packaging

Unlike other PLDs on the market, which often come in application-specific packages for consumer electronics, TI’s PLDs use standard Joint Electron Device Engineering Council (JEDEC) packaging options. This makes it easy to implement programmable logic in automotive and industrial applications.

TI PLDs also offer leaded packages with a 0.5mm pitch, ensuring excellent solderability and compatibility with automated optical inspection processes. With an extended temperature range of –40°C to 125°C and AEC Q-100 qualification, these devices are designed for long-term reliability in demanding environments.

Configure in Seconds

TI PLDs streamline the configuration process with an intuitive graphical interface. The InterConnect Studio software lets designers configure circuits without coding knowledge. Once your design is complete, you can temporarily configure the PLD for evaluation or permanently program it for production. With simple drag-and-drop components and simulation options, TI’s InterConnect Studio enables fast prototyping.

Why Choose PLDs?

- Reduce Design Complexity and Size: Consolidate up to 40 logic elements, reducing the need for discrete devices and shrinking overall solution size by up to 94%.

- Simple Design and Configuration: Quickly configure your logic design using InterConnect Studio, with no coding required.

- Standard Packaging Options: With JEDEC-approved packaging and automotive-grade reliability, TI PLDs are ready for use in industrial applications.

For more information check Texas Instruments product page.

Leave a Reply